T Premium Heat Pump or Convertible Coil C Standard Cooling Only Refrigerant Type 4 R-410A Coil Design X Direct Expansion Evaporator Coil Coil Feature C Cased A Coil A Uncased A Coil F Cased Horizontal Flat Coil Coil Width CasedUncased A 145 133 B 175 163 C 210 198 D 245 233 H 105. Microchannel all-aluminum construction provides several additional benefits.

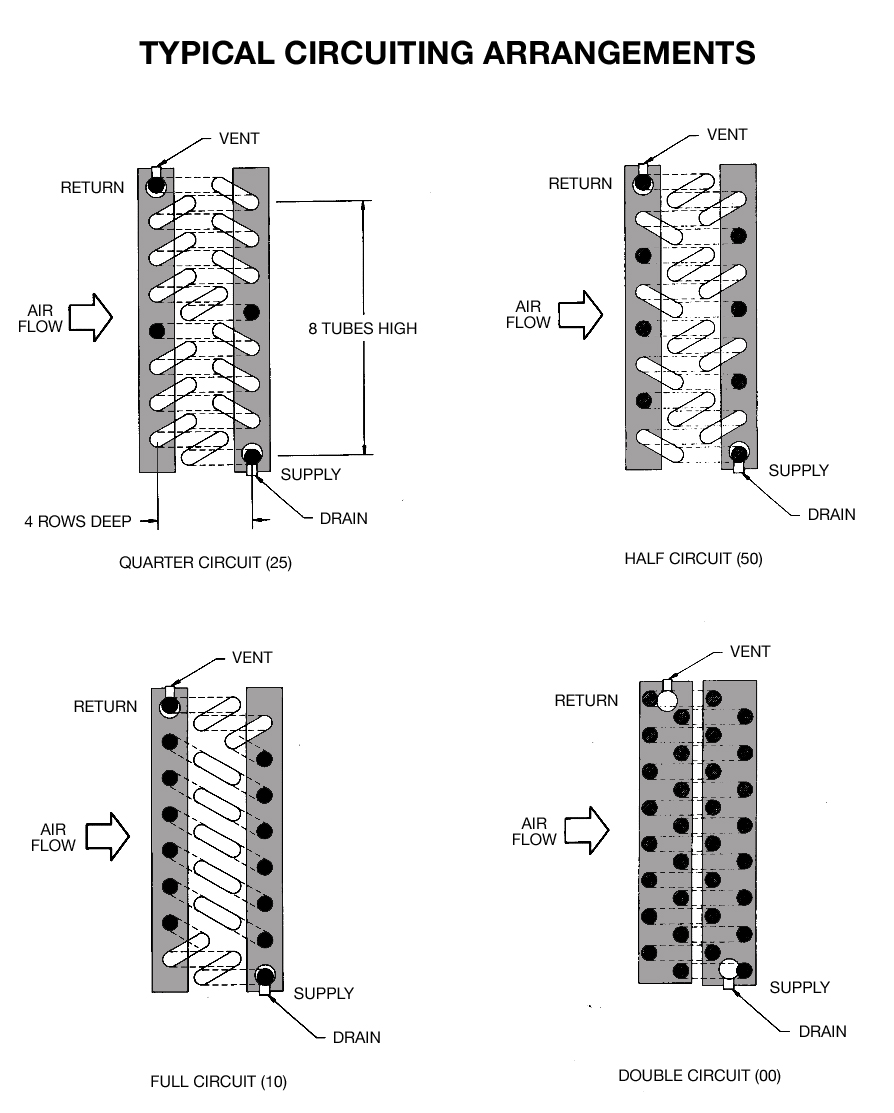

Understanding Coil Circuiting With A Simple Guide Campbell Sevey

Defrost circuit malfunction causing coil icing.

. With the CAPF3743C6 evaporator coil Goodman provides an enhanced comfort to your home. In electronics a wafer also called a slice or substrate is a thin slice of semiconductor such as a crystalline silicon c-Si used for the fabrication of integrated circuits and in photovoltaics to manufacture solar cellsThe wafer serves as the substrate for microelectronic devices built in and upon the wafer. With its ability to work with AC-only systems or with heat pumps and its ability to be installed in both the upflow or downflow orientations the CAPF3743C6 is designed to be versatile in design and to provide an efficient comfort at a low cost.

Refrigerant Circuit Single Refrigerant Metering Device Type Priston TXV Refrigerant Charge Per Circuit Kg 300 262 306 Condenser Coil Type CuAl Condenser Coil Rows FPI 2 20 Evaporator Coil Type CuAl Evaporator Coil Rows FPI 3 12 Condenser Motor Type Induction Motor - Totally Enclosed Evaporator Motor Type Electronically Commutated ECM. The major components of a chiller are selected to han-dle the refrigerant which would be evaporated at full load design conditions. The pump forces the refrigerant through the circuit of tubing and fins in the coils.

With a durable cabinet and a standard-efficiency design the GPC1448H41 is an inexpensive solution for any horizontal-discharge packaged unit application. However most systems will be called upon to deliver full load capacity for only a relatively small part of the time the unit is in. The individual room controls depending on the HVAC system design.

The liquid refrigerant evaporates in the indoor evaporator coil pulling heat out of indoor air and cooling your home. 0-60V Dual Variable supply using LM317 LM337. The condenser and cooling tower circuit is not needed.

Hot gas bypass is recommended when the load on an evaporator varies and operation of the air conditioning system is desired at lower than design conditions. Locate the evaporator coils. The fluids may be separated by a solid wall to prevent mixing or they may be in direct contact.

A pump called the compressor moves a heat transfer fluid or refrigerant between the evaporator and the condenser. As a general rule the higher the temperature of the air passing over the evaporator the higher your suction pressure will be. Transistor capacitor circuit design guide.

The equipment includes fan coil units variable air volume systems terminal reheat unit ventilators exhausters zone. Additionally hot gas bypass is used when the evaporator coil is designed for comfort cooling latent and sensible loads versus precision cooling all sensible loading. They are widely used in space heating refrigeration air conditioning power stations chemical plants petrochemical plants petroleum.

If the evaporator is located above the receiver there are three important precautions that should apply. These panels are lined with thin pieces of aluminum called fins. A heat exchanger is a system used to transfer heat between two or more fluidsHeat exchangers are used in both cooling and heating processes.

The evaporator and is pumped through the chilled water supply CHWS piping into the cooling coil. The header distributor of refrigerant to the tubes placed between the expansion valve and the evaporator is a larger pipe connected with all circuits of an evaporator to supply a certain amount of refrigerant to each circuit. Also it may cause damage to these controls or may be noisy in operation.

TXV Hunting Anytime the evaporator coil sees a reduced heat load than that it is designed to see a TXV can lose control and hunt. Their flat streamlined tubes with small ports and metallurgical tube-to-fin bo nd allow for exceptional heat transfer. Coils are typically made of copper steel or aluminum and consist of tubes bent in U-shapes and set into an A-frame design of two panels.

This is a 0-60V Dual Variable power supply circuit using LM317 and LM337 at 15A current so can build to easy with PCB layout adjustable voltage VR1 VR2. To convert 12V source to 5V DC supply for digital circuit microcontroller and More. AC Evaporator Coil Replacement Costs.

The temperature of the room air is higher than the temperature of the cool refrigerant this allows it to absorb more energy and boil the refrigerant completely into a vapour. Design engineers often have to choose between D-X evaporators Fig. This design reduces risk of leaks and provides increased coil rigidity making them more rugged on the jobsite.

4 ton 14 SEER AC-only packaged unit. There are two refrigeration circuits each with a liquid line supplying liquid refrigerant from the condenser to a TX valve adjacent to the evaporator and a suction. In many ways.

The liquid refrigerant should be delivered to the evaporator without flashing due to heating of liquid from surrounding. 97 and a water-chilling system Figs 910 and 911. It undergoes many microfabrication processes such as doping ion.

If the suction pressure is below 32 saturation temperature the evaporator coil will eventually freeze. Because a frozen evaporator coil can be the result of a blower fan stoppage or the reason the blower fan stops running a frozen coil with fan stoppage should be diagnosed and remedied. The evaporator does what the condenser does in reverse.

The evaporator receives the refrigerant and another fan blows the warm air of the room across the evaporator coil. There are also multiple D-X air-cooling evaporators connected to a single air-cooled condensing unit known as variable. The evaporator coil can freeze up as a result of indoor blower fan malfunction low refrigerant charge low outdoor temperatures or other system malfunctions.

End of the refrigeration cycle. Replacing the evaporator coil costs 600 to 2000 depending on the type brand and how difficult it is to access. Of liquid refrigerant to the evaporator to complete the refrigerant circuit.

AC Compressor Replacement Cost. The Goodman GPC1448H41 is an all-in-one outdoor AC-only packaged unit. These are usually on the air intake side of the fan coil or the outlet side of the furnace.

Within D-X systems there are split systems employing a single condensing unit and a D-X evaporator. The first thing it tells us is what the boiling temperature of the refrigerant in the evaporator is. Ideal size to cover a large house in ideal climates.

Inoperable evaporator fan motor. Devices and of the evaporator. Iced-up or dirty coil.

Low airflow across evaporator coil. A common evaporator consists of tubes fins and a header. It allows the liquid to evaporate into a gas and simultaneously collects heat.

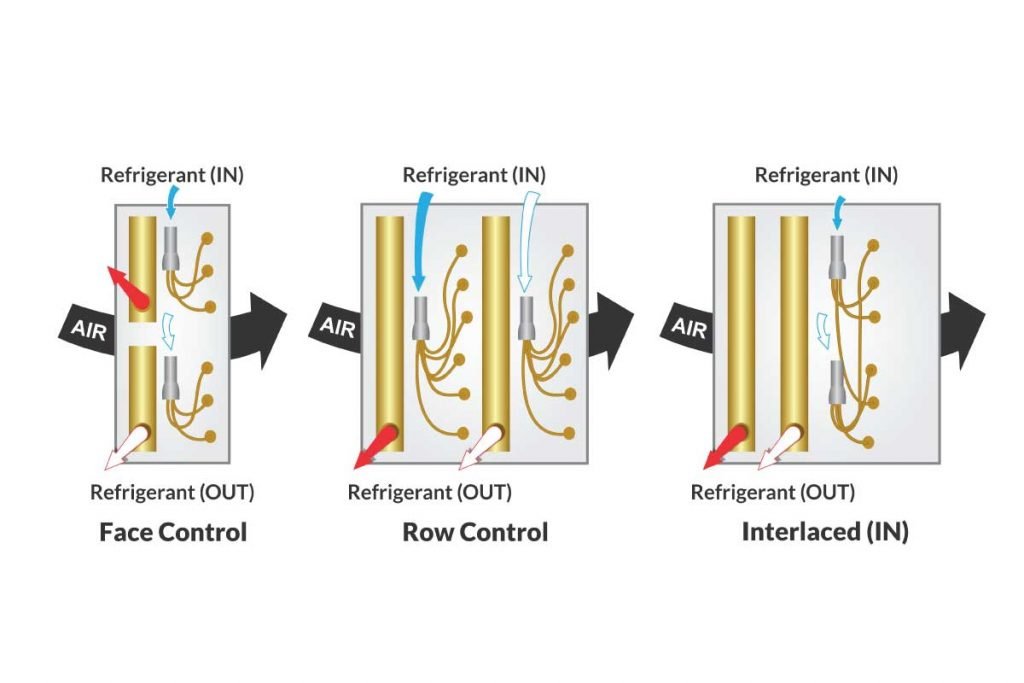

The Benefits Of Intertwined Circuiting In Split Coils Fabtech

Pdf Design Of Evaporator Cooling Coil For Cooling Load

Evaporator Coils Madok Manufacturing Inc

Chilled Water Cooling Coils Circuiting Made Easy

0 comments

Post a Comment